Automatic Horizontal Take-Off

The AUTOMATIC HORIZONTAL TAKE-OFF is a modern and sophisticated system for the extraction of the tiles from the Press and the subsequent transfer to the treatment line of the same. By depositing the tiles in horizontal position, on metal trays, their proper rest is ensured, resulting in an optimum quality of the final product.

PROCESS

-

Entrance of the tray towers with tiles already set.

-

Unstacking of the tray towers to go through one by one

-

Unloading of tiles, using suction cups, from the tray to a discharge train

-

Cleaning of the tray by the use of a rotating metal brush with displacement.

-

Loading of tiles, using suction cups, from the press blade, to deposit them on the tray

-

Stacking of each of the trays to form towers

-

Exit of the tray towers with the tiles for setting

KEY FEATURES

CONFIGURATION

Possibility of machine manufacturing with 7 stations to work with Press and finishing line together.

Possibility of machine manufacturing with 6 stations to work with Press and finishing line independently.

Completely adaptable to any Press size thanks to the adaptation of the suction cups to any tile format.

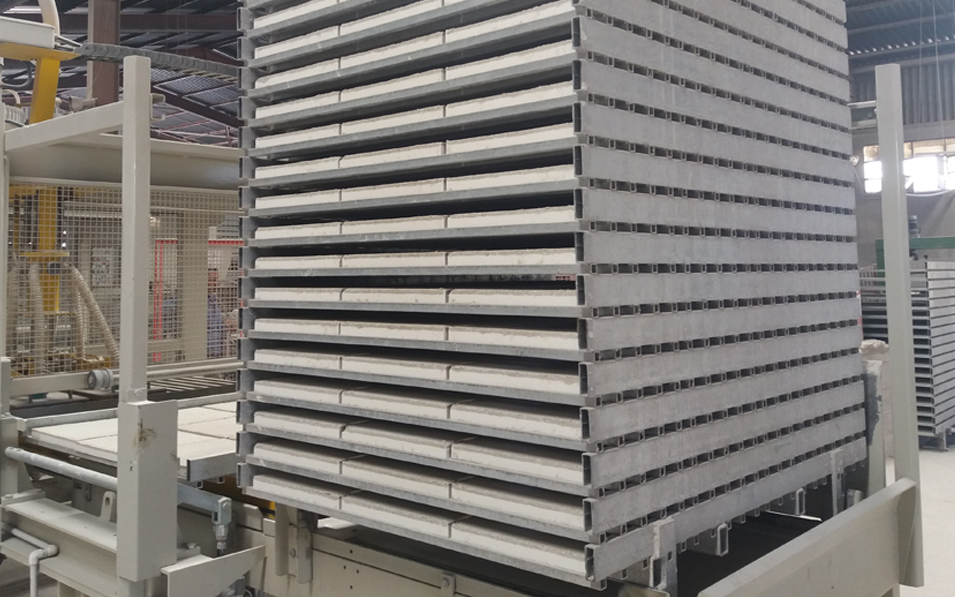

METAL TRAYS

Possibility of choosing between several tray sizes, depending on the number of tiles to be extracted from the Press.

Total tray height between 80 and 120mm, depending on the tile thickness.

Available sizes: 1.250 (L) x 890 (W) mm, 1.420 x 890mm, 1.100 x 1.090mm, 1.250 x 1,090mm, 1.420 x 1.090mm and 1.700 x 1.300mm.

Option to install a metal sheet on the crossbeams of the tray, for the proper rest of the tile.

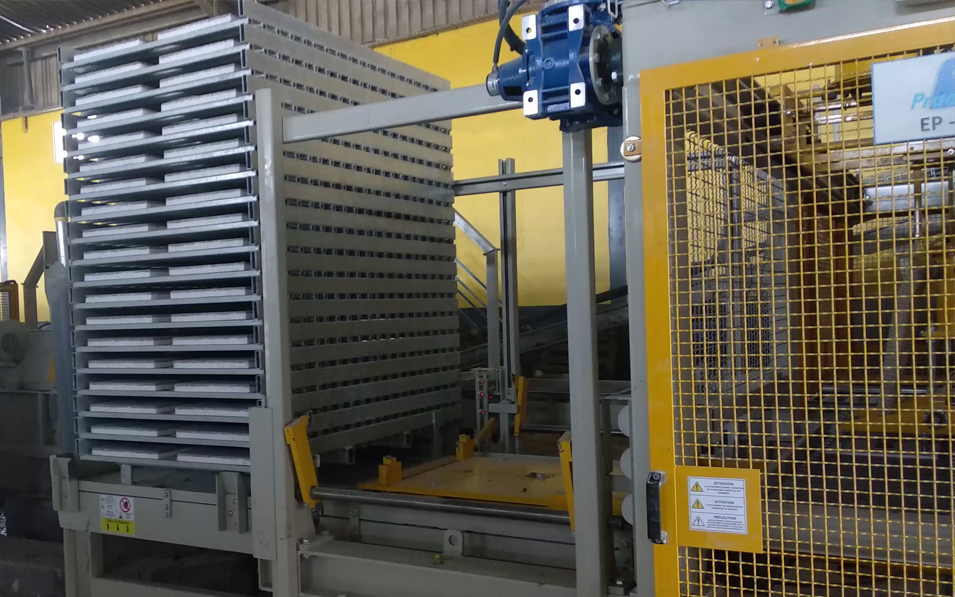

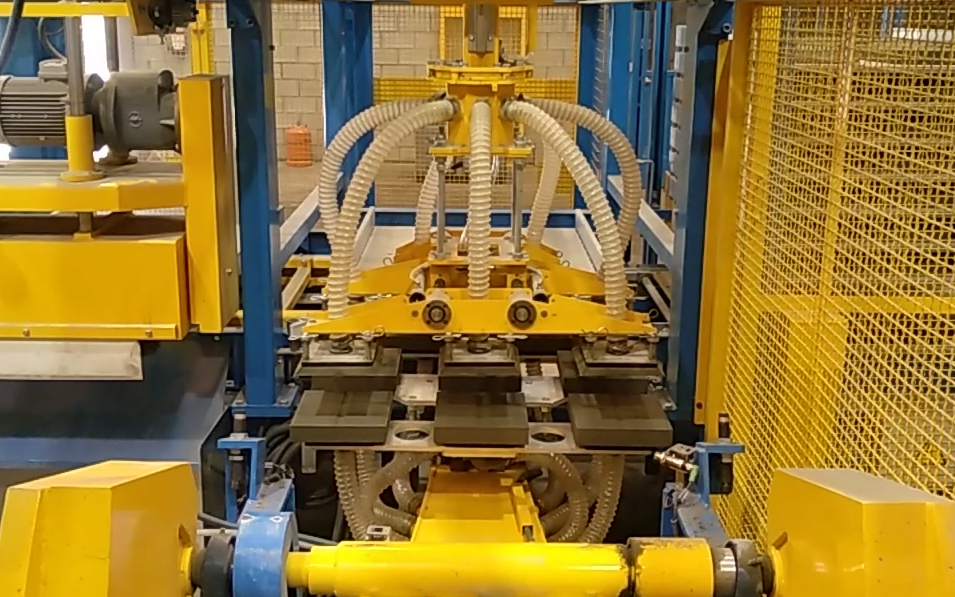

UN-STACKER AND STACKER

Entrance of the tray towers to the un-stacker and exit of the same from the stacker, through chain conveyor.

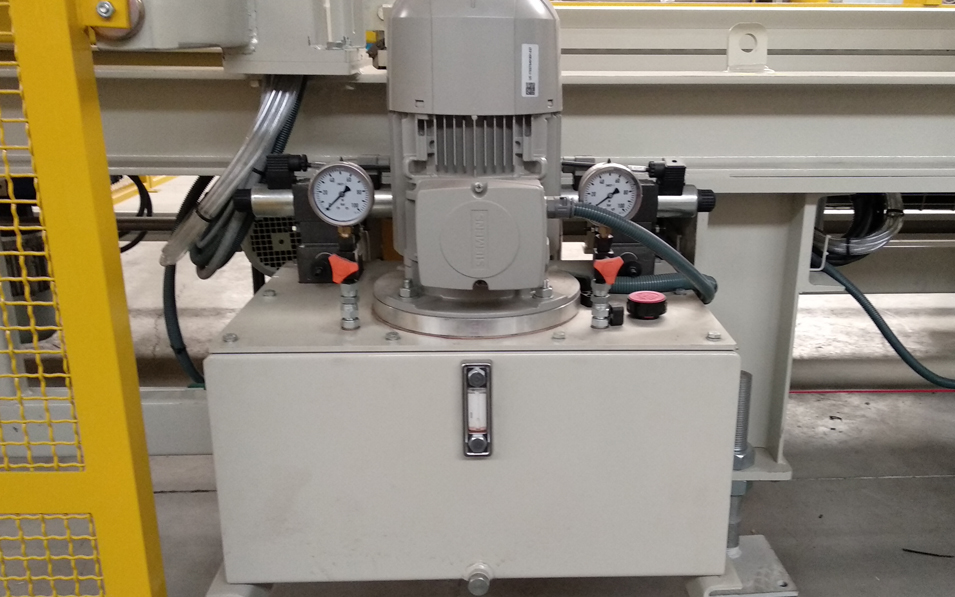

Platform for stacking and unstacking of trays, by the use of a hydraulic cylinder.

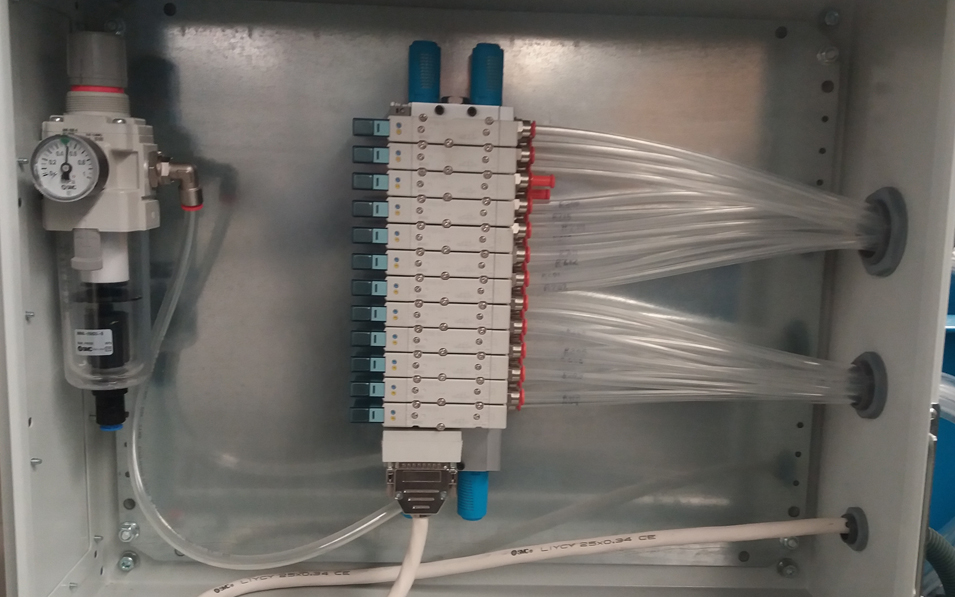

Tray connection grippers, by the use of a pneumatic drive.

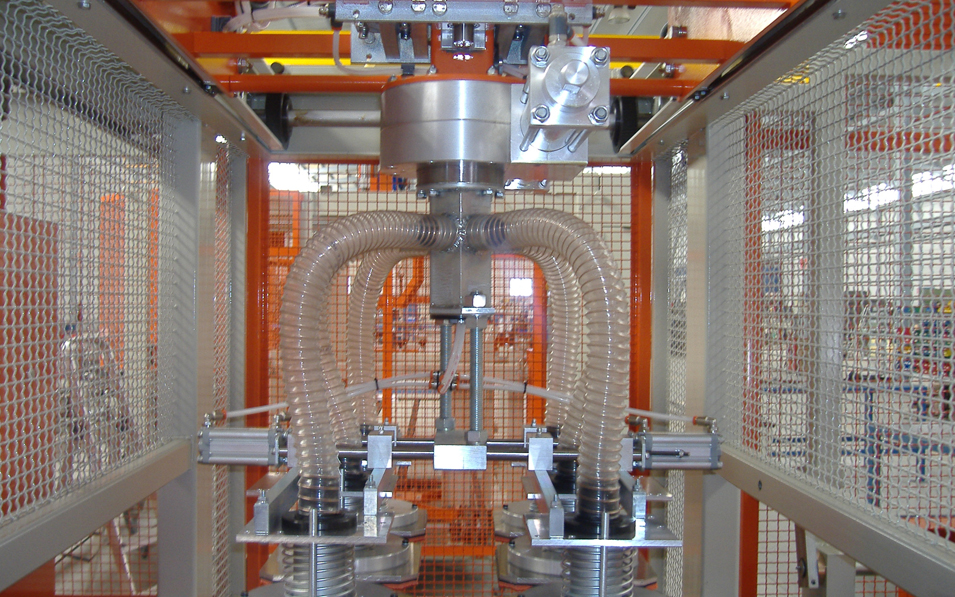

LOADING AND UNLOADING SUCTION CUPS

Tile displacement trolley, moved by two belts and equipped with an encoder for different positioning.

Option to add lateral displacement, to take maximum advantage of the space in the metal trays, depending on the removed tile number.

Option to add 90º rotation on the suction head to adapt the tiles to the tray format.

Head fabrication option with tile approximation system.

SUCTION CUP TURNER

Option to install a Suction Cup Turner, between the Press and the Horizontal Extractor.

System equipped with suction cups for the extraction of tiles by vacuum.

Suction cup-rotating arm at 180°, controlled with speed variator.

Removes the tiles from the Press blade and turn them to be extracted by the suction cup of the Horizontal Extractor.

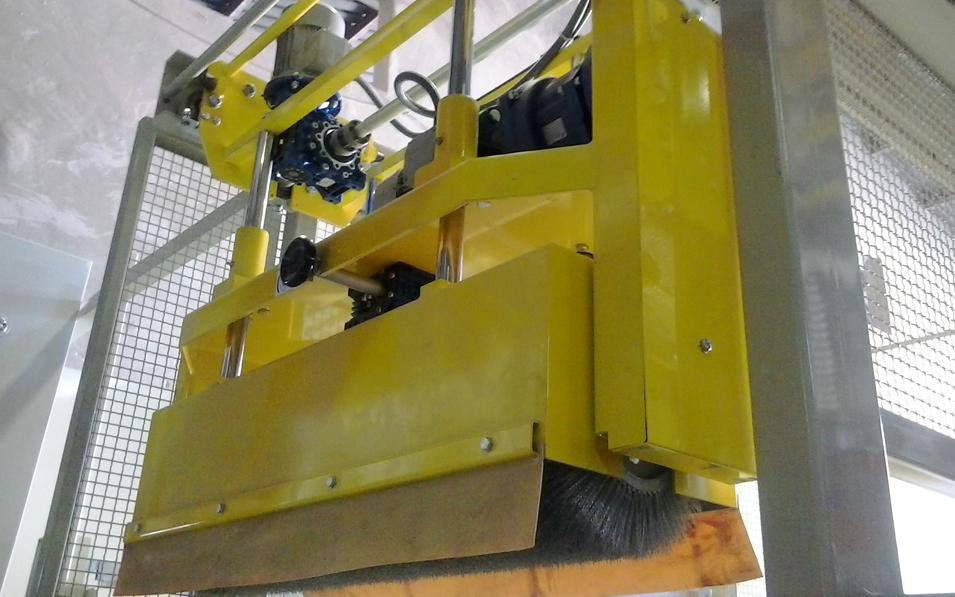

CLEANING BRUSH

Option to add a cleaning system consisting of a trolley with a metal brush.

Circular metal brush that moves along the tray after the tiles have been unloaded.

Innovative system to keep the trays in an optimal condition for loading the tiles.

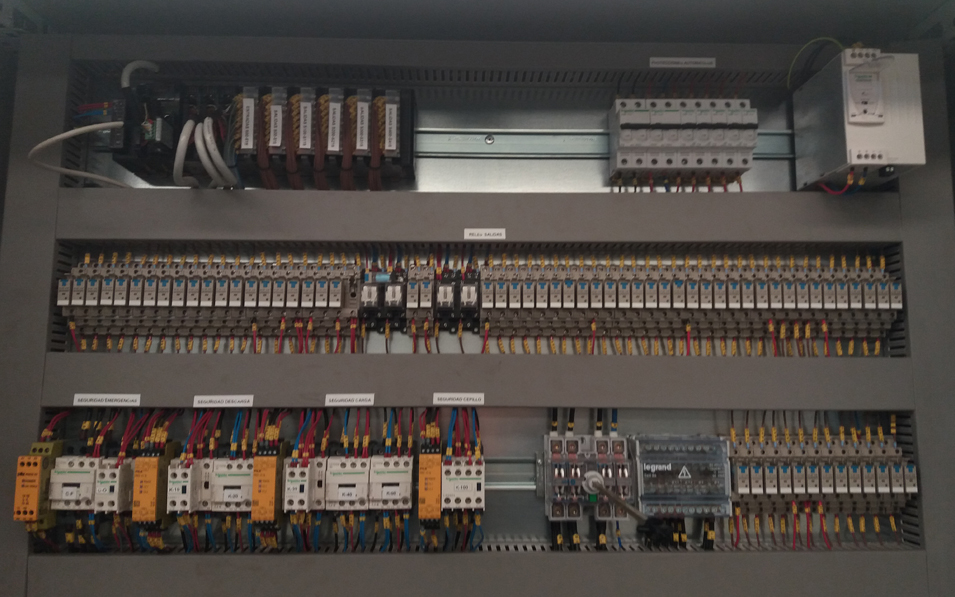

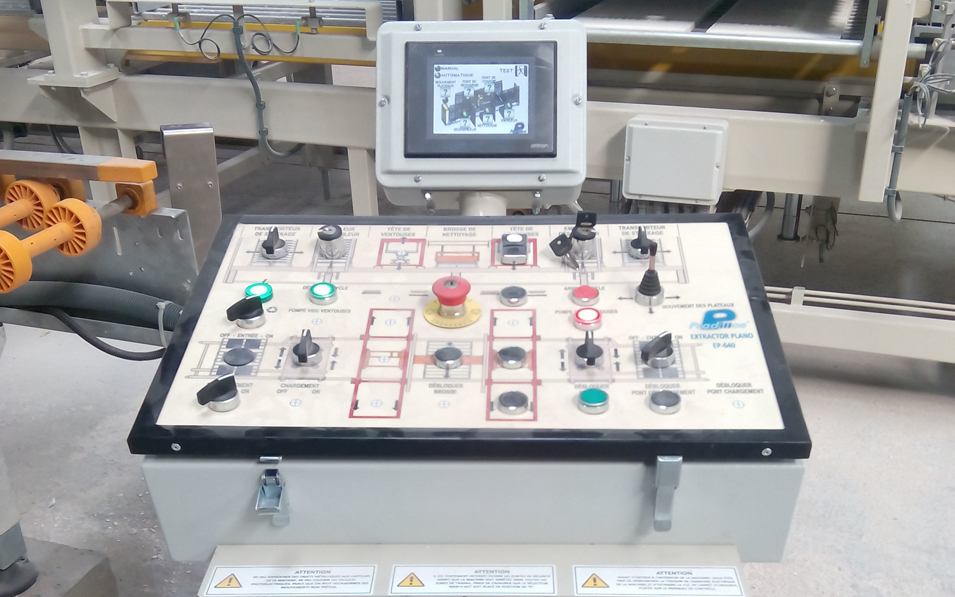

CONTROL SYSTEM

Complete electrical cabinet, with PLC control, for automatic operation of the entire installation.

Full-color 5.6`` touch screen for monitoring the machine as a whole and changing parameters.

Control panel for the operating mode selection and total control of all elements manually.

Approved and integrated safety systems for the protection of machine operators.

AVAILABLE MODELS

EP-646

EP-647

EP-846

EP-847

Contact us and we will advise you on your project