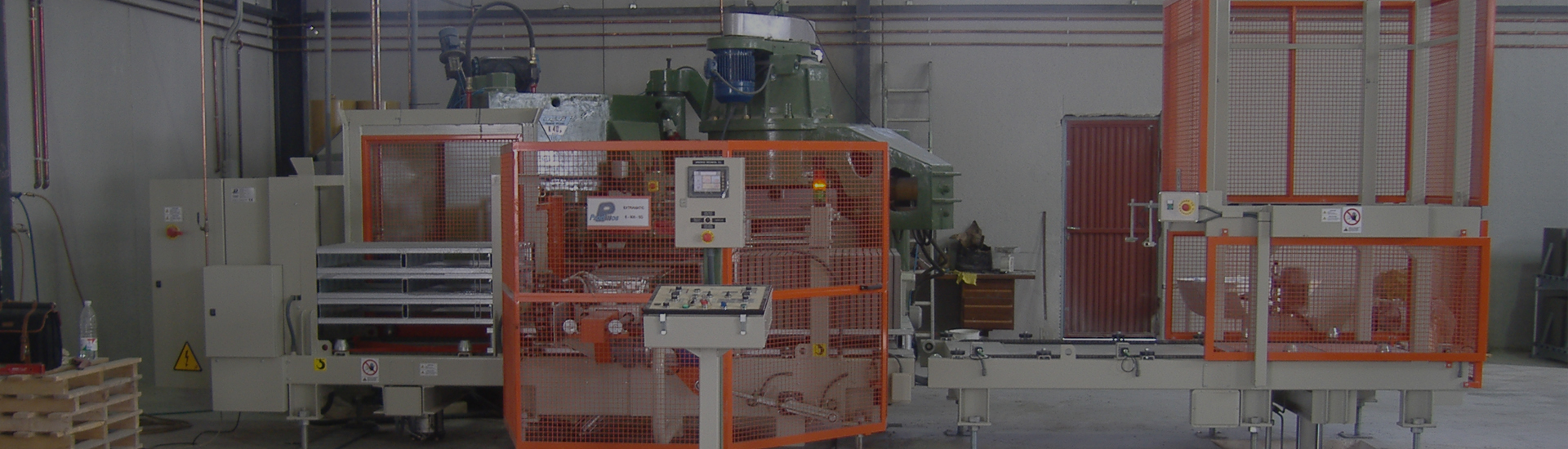

Vertical Extractor

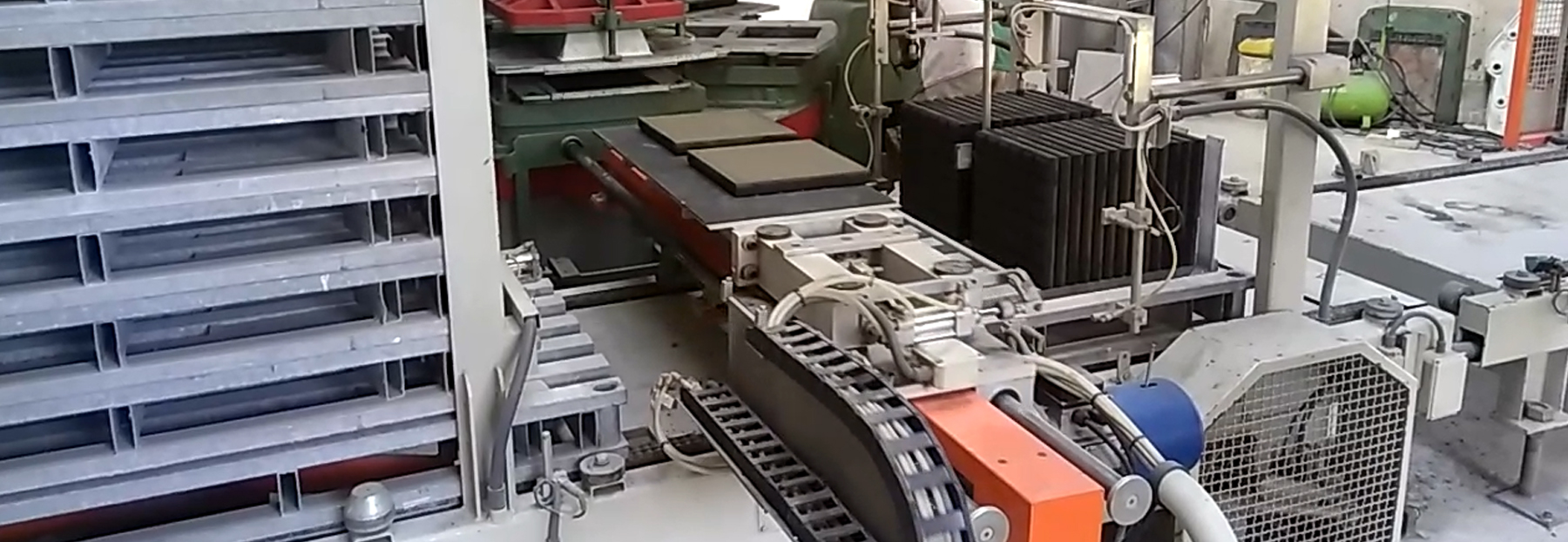

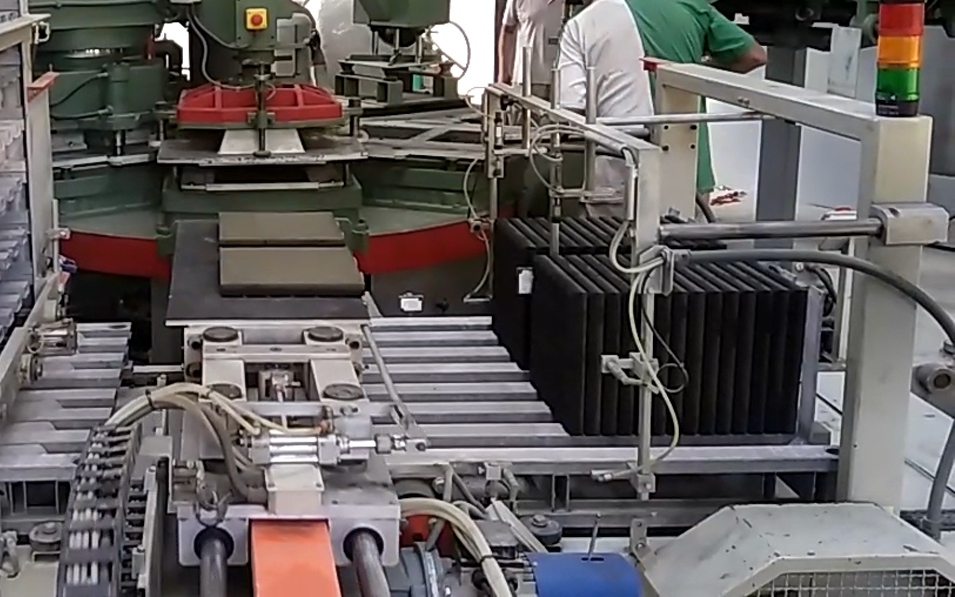

The VERTICAL EXTRACTOR is an alternative automation system to the Horizontal Extractor, although it is completely different. This machine has an extractor carriage that enters the Press mold to extract the tiles and deposit them in vertical position on metal pallets.

PROCESS

-

Entrance of a metal pallet tower directly into the automatic destacker

-

Unstacking of metal pallets to go through one by one

-

Lifting metallic support that will support the first tile row

-

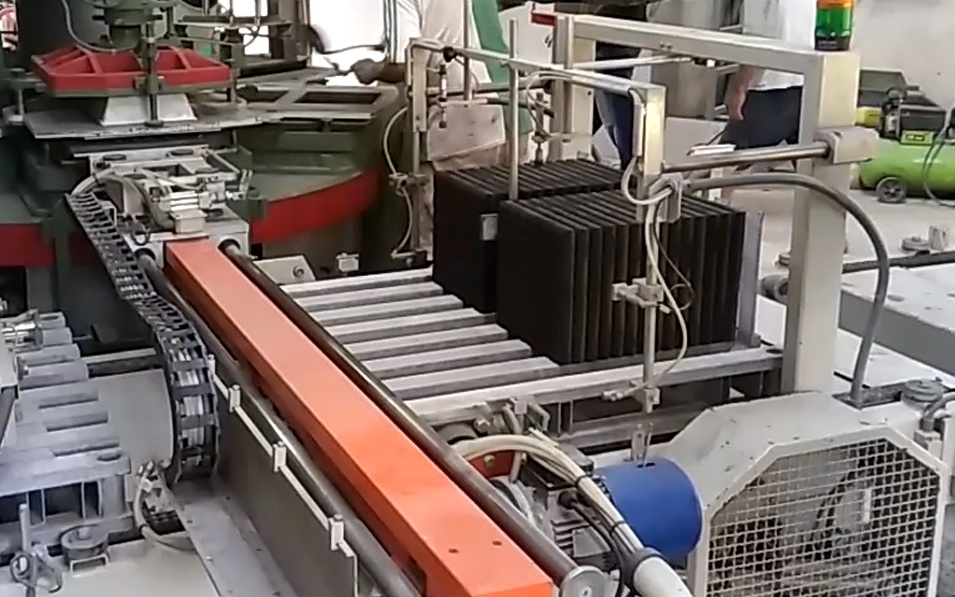

Discharge of the tiles, using the extractor carriage, in vertical position

-

Once the pallet is completed, an operator will place some support brackets to avoid the overturning of the tiles and pillars for stacking

-

Stacking of 2 to 3 loaded metal pallets, to form towers

KEY FEATURES

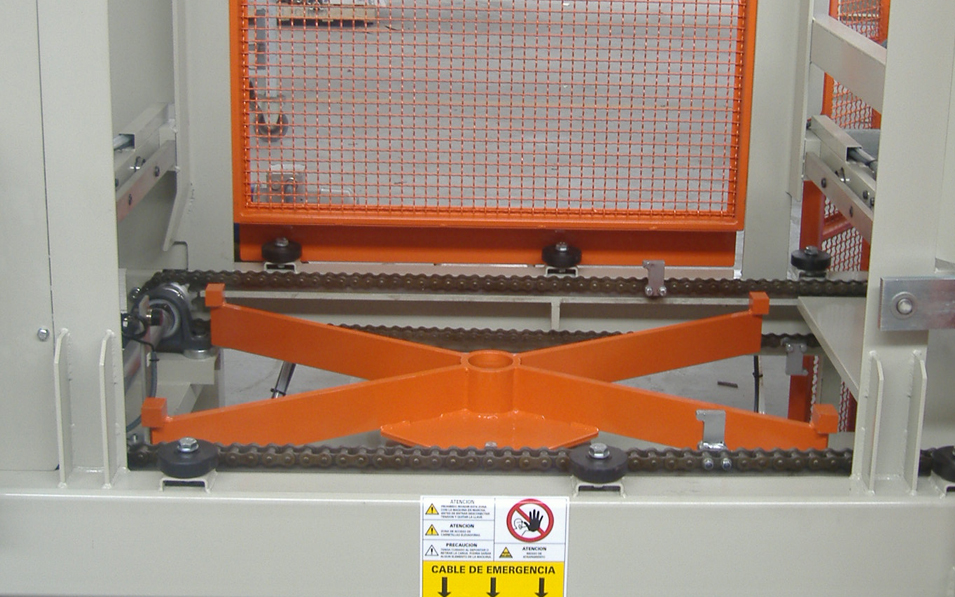

PALLET UN-STACKER

Storage and unstacking of empty metal pallets, by the use of a large pneumatic cylinder.

Pallet connection grippers, by pneumatic drive.

Pallet chain conveyors to move to the loading area.

METAL PALLETS

Possibility of choosing between 2 pallet widths, depending on whether you wish to deposit 1 or 2 tile rows of 400x400mm.

Available pallet sizes: 1.150x700mm and 1.150x900mm.

Supplied with final support to prevent overturning of loaded tiles and pillars for stacking.

EXTRACTOR CARRIAGE

Extraction carriage with displacement by belt and toothed pulleys.

Equipped with an encoder for different positioning, depending on whether there are one or two positions on the pallet.

Turning of the extractor carriage by the use of a rod drive.

Pneumatic grippers in the carriage to hold the tiles at the turning moment.

Tile fall or break detection system.

STACKER

Storage and stacking of loaded metal pallets, by the use of a large hydraulic cylinder.

Pallet connection grippers, by pneumatic drive.

Chain pallet conveyors to move to the stacking area.

Option to install an automatic system, to detect that the pallet pillars are placed, before entering the stacker.

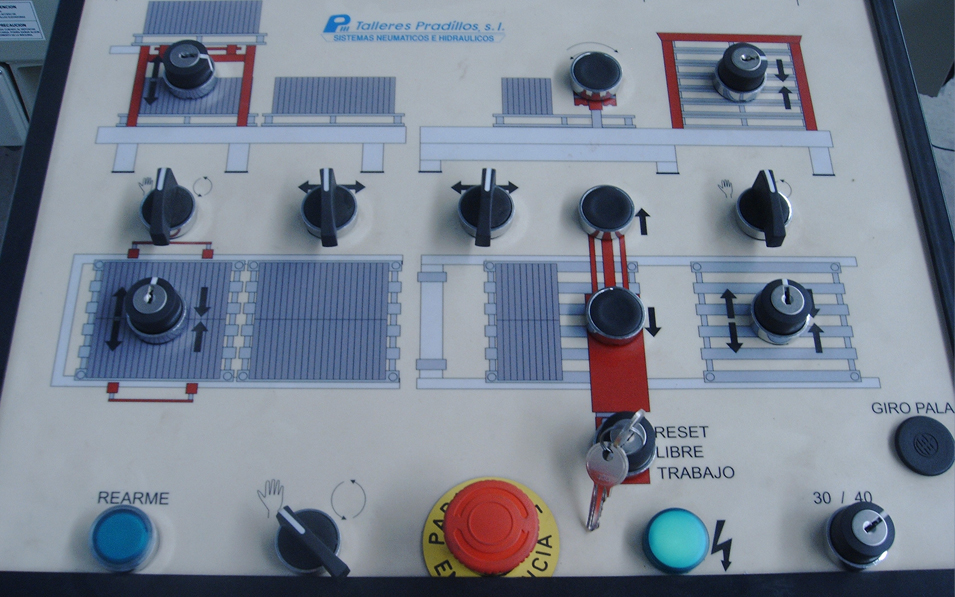

CONTROL SYSTEM

Complete electrical cabinet, with PLC control, for automatic operation of the entire installation.

Control panel for the operating mode selection and total control of all elements manually.

Approved and integrated safety systems for the protection of machine operators.

AVAILABLE MODELS

E-700

E-900

Contact us and we will advise you on your project