Concrete Plant

The CONCRETE PLANT is one of the essential elements within the production line of terrazzo tiles, because this system is the one that will perform the dosing and mixing of the raw material, in an automatic and completely uniform way, which will allow obtaining a good quality tile

PROCESS

-

Loading of the raw material in the hoppers

-

Start of the cycle and automatic weighing of aggregates and cement

-

Unloading of aggregates and cement in the Mixer

-

Automatic water dosing

-

Mixing all the elements

-

Unloading of the mixture into the face-to-face and/or reverse dosing system

KEY FEATURES

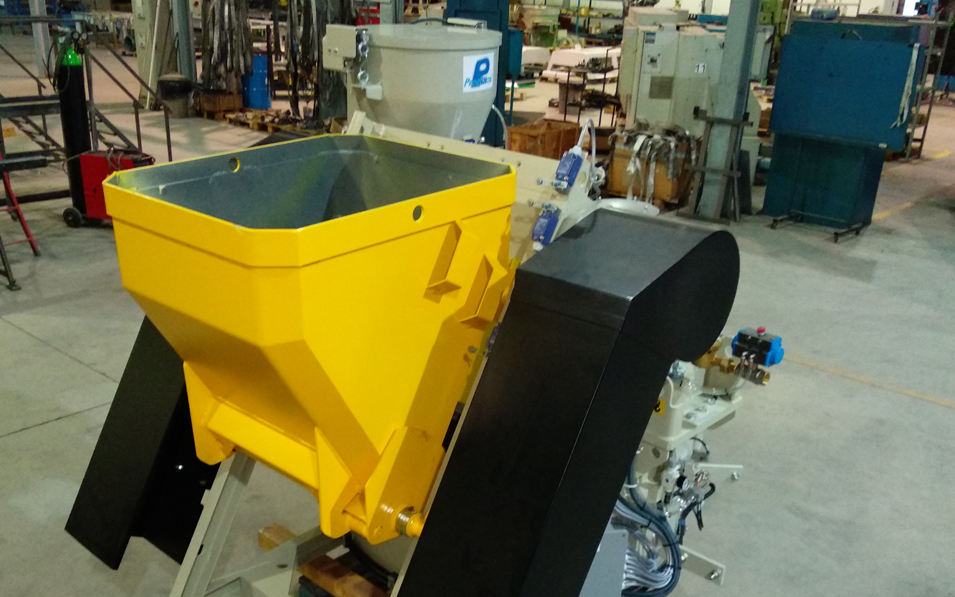

HOPPERS

Possibility of choosing the number of hoppers.

Load capacity from 4m3 by hopper.

Dosing of aggregates by the use of unloading tapes.

Possibility of emptying the hoppers by the use of unloading tapes.

CEMENT

Option to store cement in silo, with minimum level probe.

Option to store the cement in a special 3m3 capacity hopper

Scale for the independent cement weighing.

Possibility of installing the scale on the mixer or on the weighing tape.

Manufacture of customized augers for cement dosing.

MIXER

Planetary mixers with capacity from 250 litres (vibrated concrete).

Possibility of loading the Mixer by the use of skip or tape.

Accessories such as: platform, ladder and support column.

Automatic system option for water dosing.

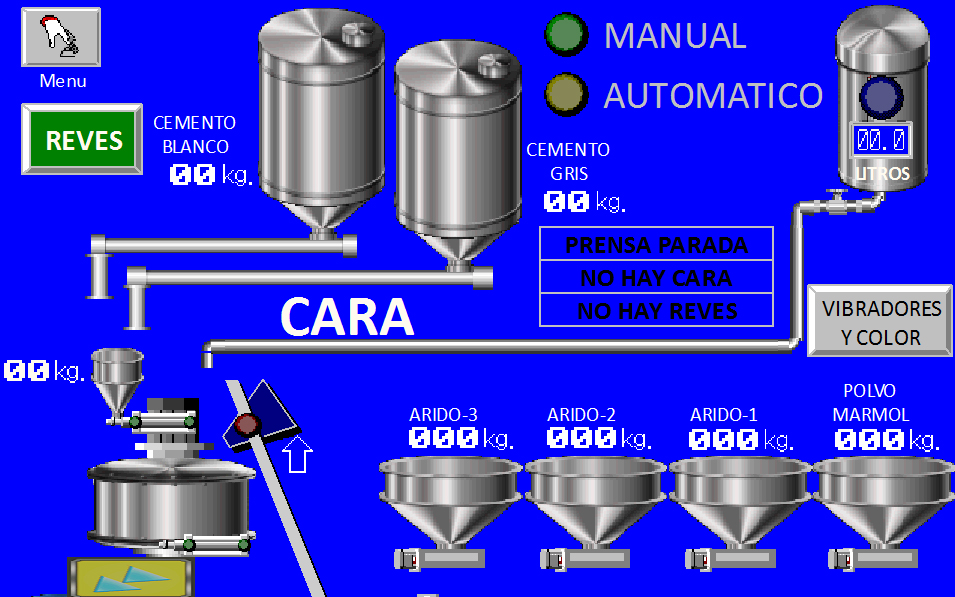

CONTROL SYSTEM

Complete electrical cabinet, with PLC control, for automatic operation of the entire installation.

10.4`` touch screen option in full color for the supervision of the entire installation.

Register capacity of more than 100 formulas with the screen option.

Auxiliary control buttons for the total control of all elements manually.

AVAILABLE MODELS

BT4-22/22

BT4-25/22

BT2-22/22

BT2-25/22

Contact us and we will advise you on your project