Grinding-Polishing Machine

The GRINDING-POLISHING MACHINE is an indispensable machine, if you are going to manufacture indoor or outdoor tiles that need polishing. As its name indicates, the function of this machine is to perform the surface treatment of the tiles, depending on whether they are only polished or also polished.

PROCESS

-

Entrance of the tiles, fed with the face upwards

-

Grinding them y the use of diamond and/or abrasive heads

-

Polishing tiles, using the Frankfurt heads

-

Their exit all with the same finish

-

Drying of the tiles, in case of installation of a drying conveyor

-

Manual or automatic extraction of them for palletizing

KEY FEATURES

CONFIGURATION

Modular assembly, with the option of installing 2 heads per module.

Depending on the width of the belt, 1 or 2 tile rows can be polished and/or glazed.

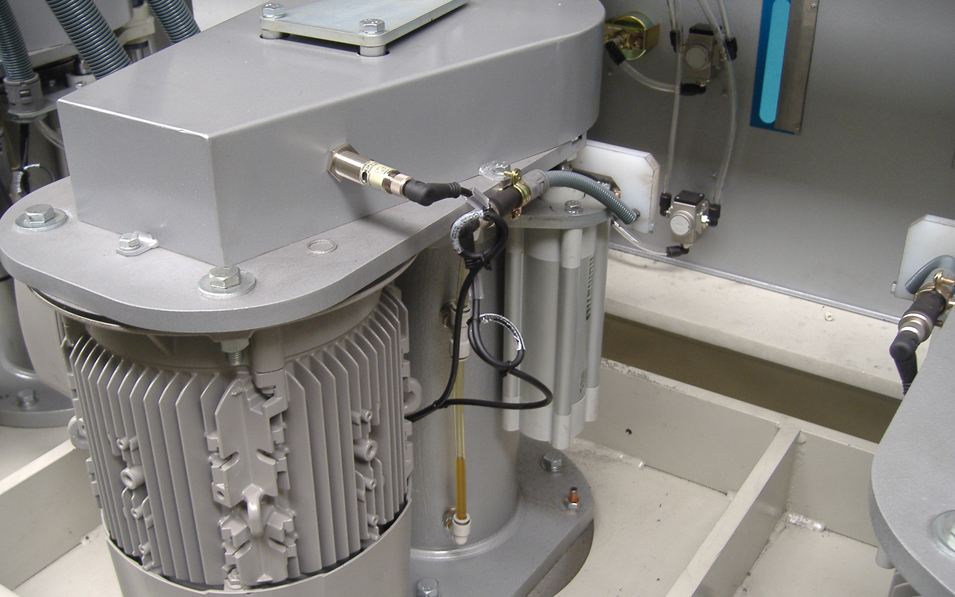

Power of the motors depending on the final configuration of all the heads.

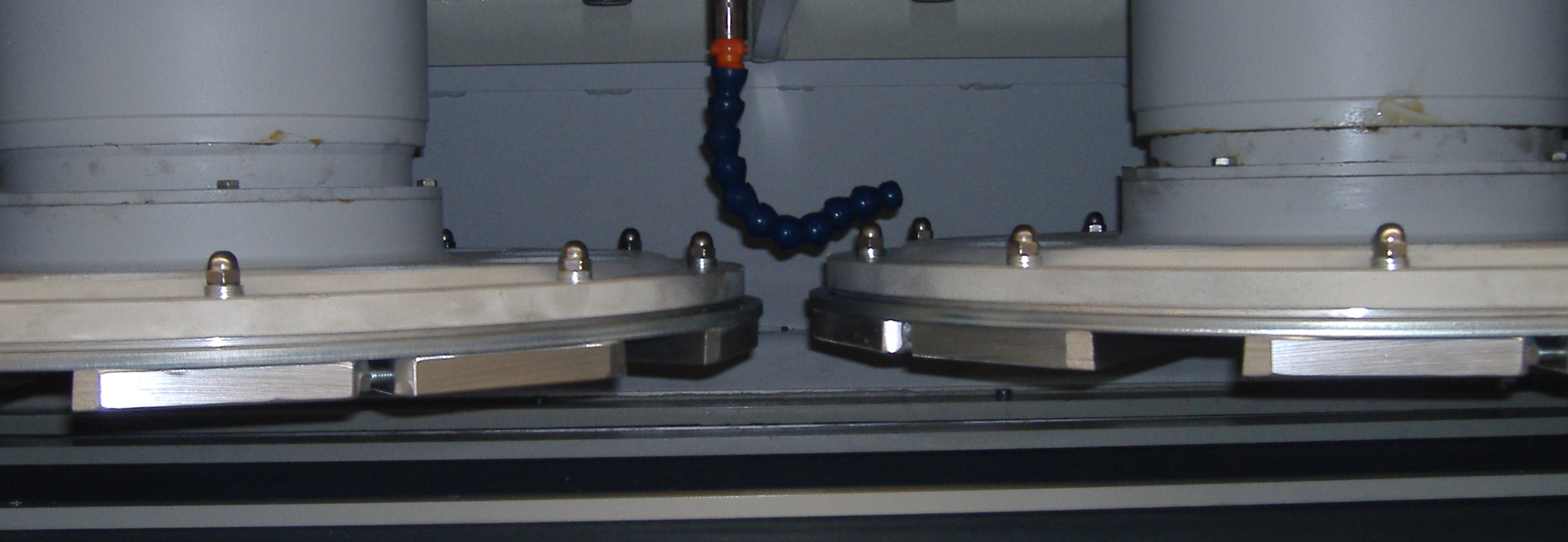

GRINDING HEADS

Standard plate diameters: 570mm and 740mm, depending on the tile format to be grinded.

All the wheels are abrasive, regardless of the plate size, are quick-hitch, which facilitates the change after abrasion.

Possibility of choosing between mechanical elevation system or hydraulic system.

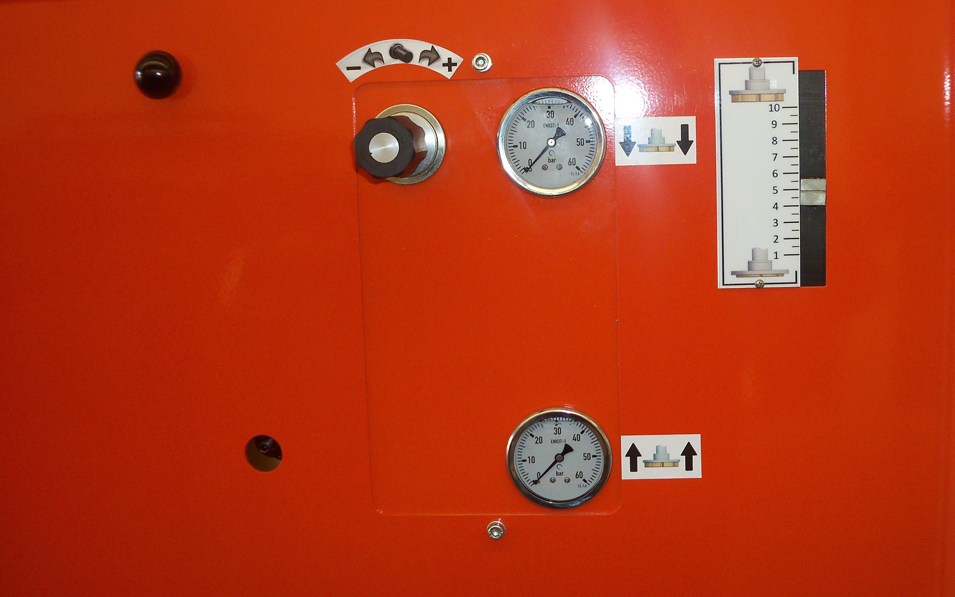

Electronic control of the abrasive pressure of the polishing on the tile.

Maximum and minimum height stops on each head, with abrasion alarm.

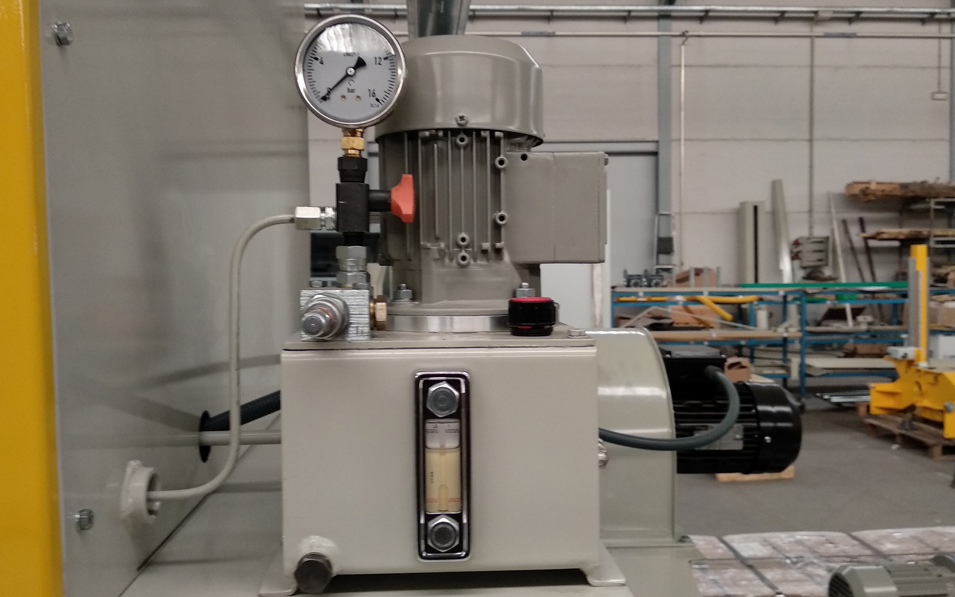

Automatic lubrication system for the inside of the heads by the use of an oil pump.

POLISHING HEADS

Standard plate diameters: 570mm and 740mm, depending on the format of the tiles to be polished.

Possibility of installing a swing system, especially in 800mm belt width.

All the wheels are of Frankfurt, regardless of the plate size, are quick-hitch, which facilitates the change after abrasion.

Pneumatic elevation system, by the use of two cylinders attached in the head.

Minimum height stops on each head, with abrasion alarm.

Automatic lubrication system for the inside of the heads by the use of an oil pump.

CONVEYOR BELT

Small roll conveyor at the entrance of the machine for the storage of some tiles.

Standard belt widths: 600mm and 800mm.

Regulation of the belt speed and the machine conveyors by the use of speed variators.

Regulation of the band guides by the use of a rotating wheel, according to the tile format to be calibrated.

Fan installed at the exit of the tiles for the partial drying of them (in case of not having a drying conveyor).

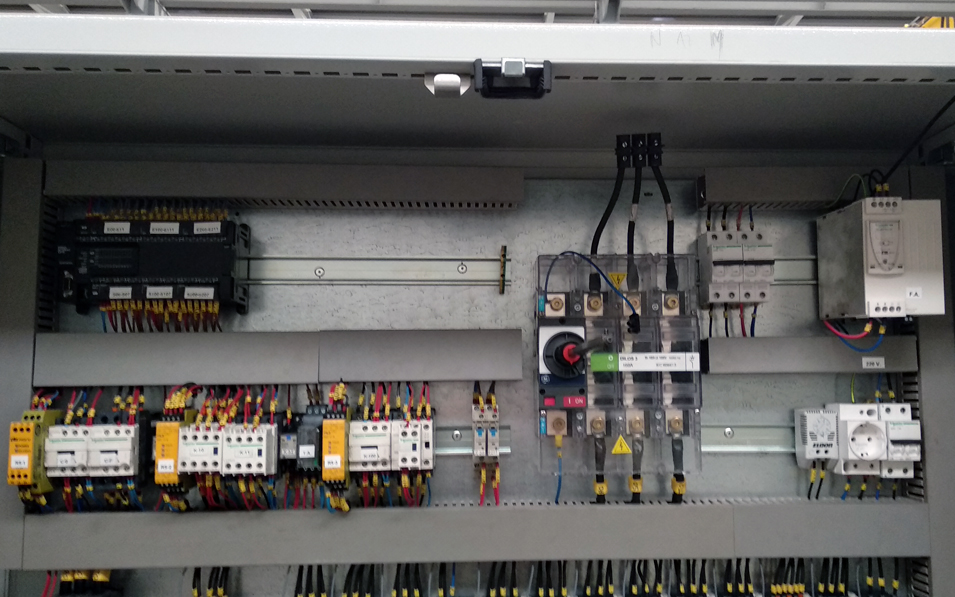

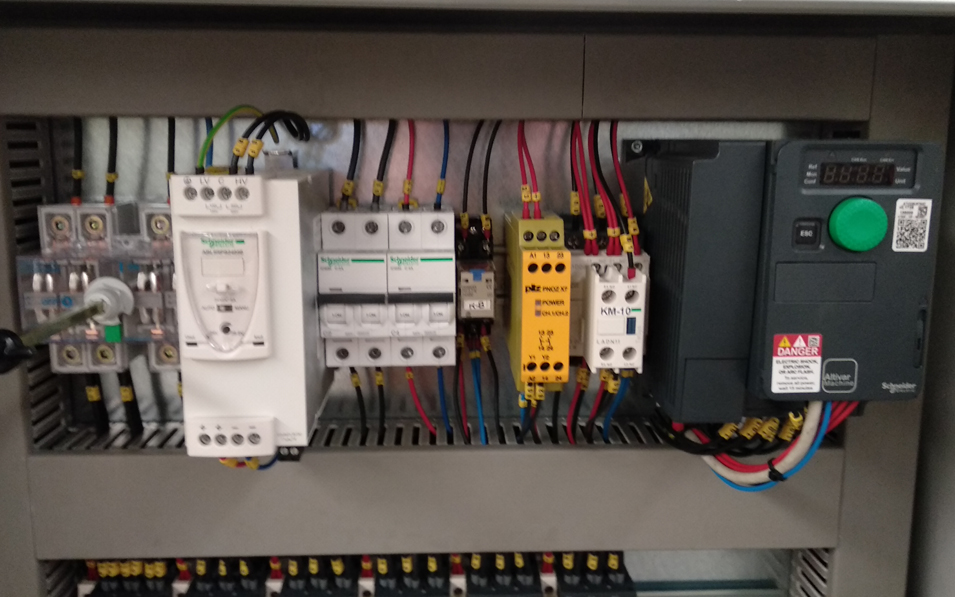

CONTROL SYSTEM

Complete electrical cabinet, with PLC control, for automatic operation of the entire installation.

Control panel every 2 heads, with digital height display, ammeters and control elements.

Approved and integrated safety systems for the protection of machine operators.

DRYING CONVEYOR

Roll conveyor at the exit of the Grinding-Polishing machine equipped with high flow fans.

Fans installed in the upper part of the conveyor, for drying the visible face of the tile.

Fans installed in the lower part of the conveyor, for drying the reverse side of the tile.

Possibility of choosing the number of fans to be installed.

Independent control system, with electrical cabinet and control panel.

AVAILABLE MODELS

PD600

PD800

Contact us and we will advise you on your project