Skirting Production Line

The SKIRTING PRODUCTION LINE is an auxiliary machine, but highly recommended, as its main purpose is to take advantage of the tiles with some kind of defect. What is done is that the tile is cut in equal parts, discarding the defective part. After this, a beveling and reducing treatment is applied to obtain baseboards ready for sale.

PROCESS

Entry of the defective tiles to the Cutter

Cutting them in equal parts, discarding the defective part

Transport of the cut strips, by an automatic conveyor or manually

Entry of the cut strips, in vertical position, in the beveling machine

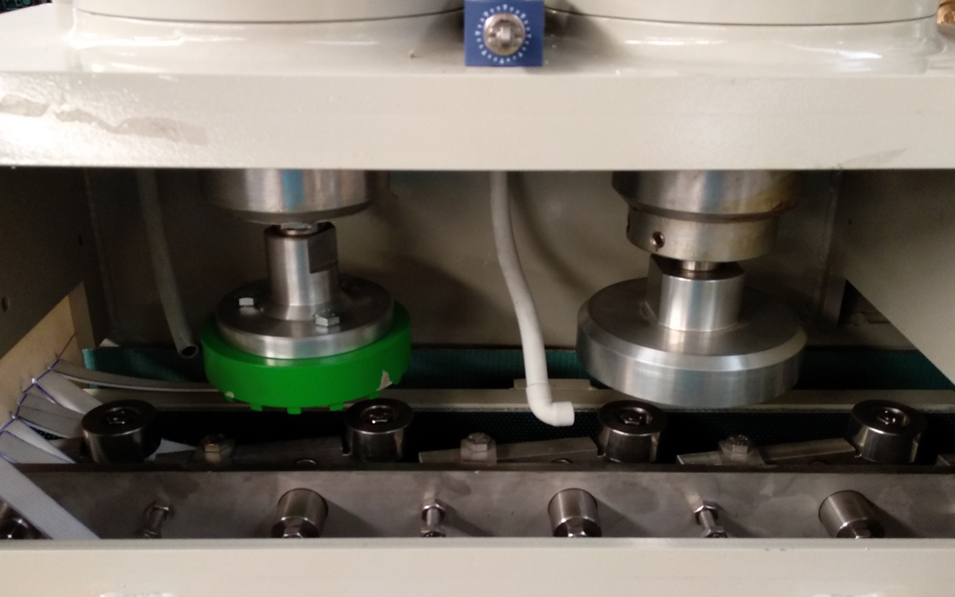

Calibration of the upper part of the strips with 2 heads

Beveling and polishing for the finishing of the baseboard with 4 heads

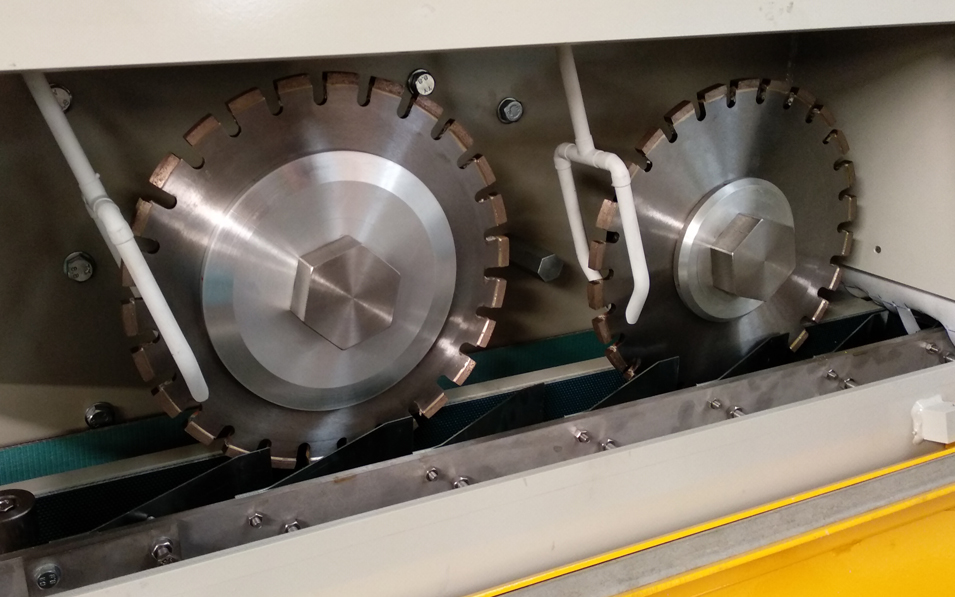

Reducing the thickness of the baseboard with 2 cutting discs

Exit of the baseboard finished and ready for packing

KEY FEATURES

CONFIGURATION

Complete line is composed of 3 elements: Cutter, Automatic Union Conveyor and Beveling Machine.

When installing the complete line, only one operator will be needed to insert the tiles and extract the finished baseboards.

Possibility of acquiring only the Cutter and the Beveling Machine, without the Automatic Union Conveyor.

CUTTER MACHINE C-500

Roller conveyor at the entrance of the machine with space to store some tiles.

Standard belt width: 500mm.

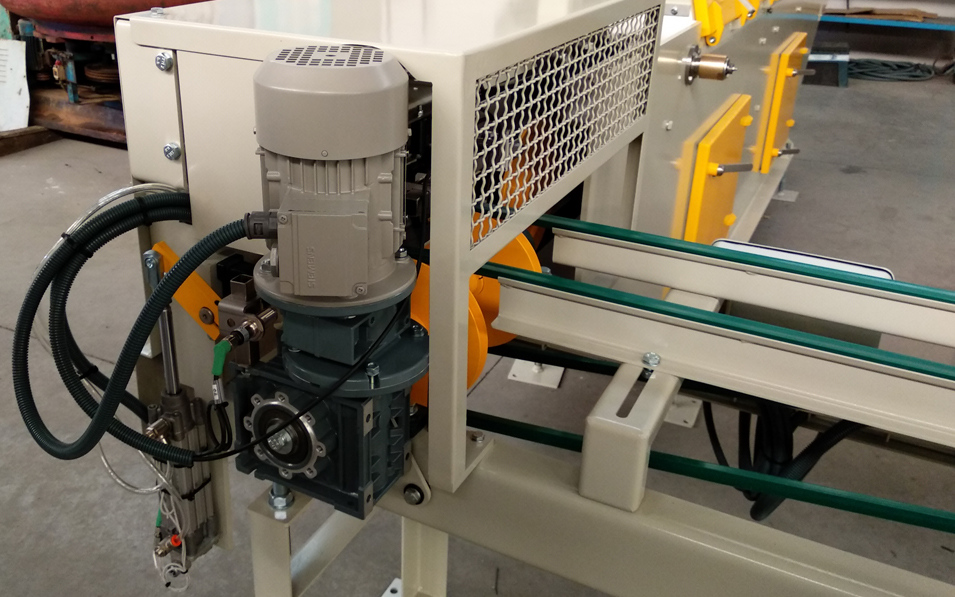

Regulation of the belt speed of the machine by the use of a variable speed drive.

Regulation of the belt guides manually, according to the format of the tile to be cut.

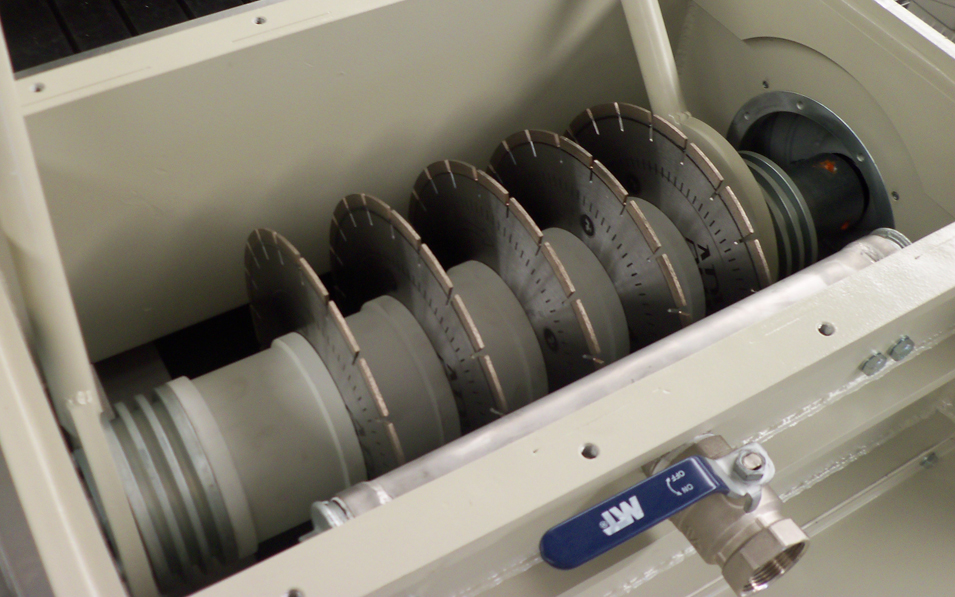

Multi-disc shaft with spacers between the discs to define the width of the strips to be cut.

Fan installed at the exit of the tiles for partial drying of them.

Complete electrical cabinet, with PLC control, for automatic operation of the whole machine.

AUTOMATIC UNION CONVEYOR

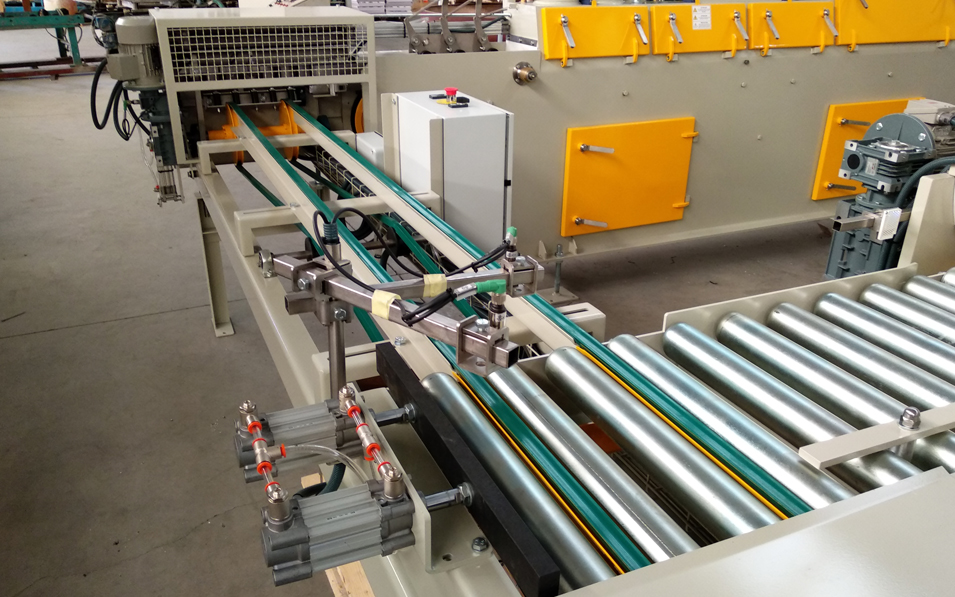

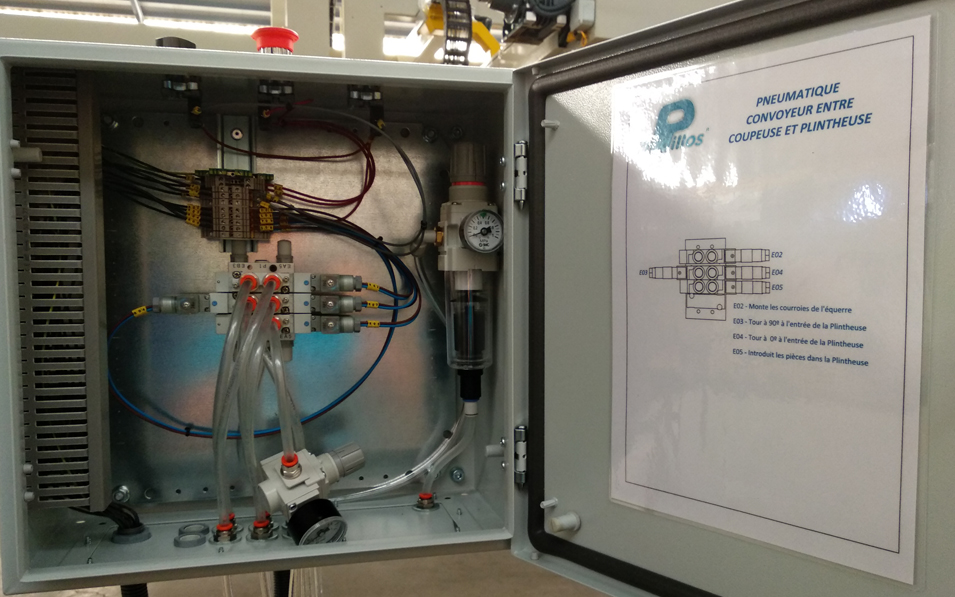

Composed of a roll train at the exit of the cutter, a belt conveyor and a 90° turning device of the strips.

90º turning device, equipped with pneumatic pusher to insert the strips into the Beveling machine.

BEVELING MACHINE BS6/100

Automatic belt stop system, in case of the machine is without piece supply at the entrance.

Regulation of the belt speed of the machine by the use of a variable speed drive.

Equipped with 2 heads for the upper part of the baseboard: 1 head (fixed) diamond and 1 abresive head (pneumatic).

Equipped also with 4 heads for the beveler at 45º of the baseboard: 1 head (fixed) diamond and 3 abresive heads (pneumatic).

To reduce the thickness of the baseboard, the machine has 2 cutting discs.

Possibility of regulating the cut width of the discs, to have a more or less wide baseboard, by the use of an easily adjustable system.

Automatic system, by the use of a pneumatic cylinder, for the exit of the finished baseboards and depositing them on rolls.

Complete electrical cabinet, for automatic operation of the whole machine and analog visualizers for electric consumption of the heads.

AVAILABLE MODELS

C-500

BS6-100

Contact us and we will advise you on your project