Roll Turnover Machine

The ROLL TURNOVER MACHINE is an accessory of the Horizontal Palletizer, used to put the face of a tile against the face of another when they are being deposited on the pallet. In this way, any damage to the visible face of the tile is prevented. The layers, which will form the pallet, are turned to 180º, one yes and the next one no and so on until the total load of the pallet.

PROCESS

-

Entrance of the tile rows formed in the grouping train

-

Closing of the rolls that form the Turner train

-

180º turn of all the tiles to face them down

-

Depending on the tile size, it will turn more or less rows per layer

-

Exit of the tiles towards the Horizontal Palletizer positioning conveyor

KEY FEATURES

CONFIGURATION

Option to choose the width of the turning rolls, depending on the number of tiles per row.

Depending on the total width of the tile rows, the width of the rolls of the Turner will be 1.160mm or 1.360mm.

Roller conveyor at the machine entrance and exit for the transport of the tiles.

Regulation of the train speed and the machine turn by means of variable speed drives.

CONTROL SYSTEM

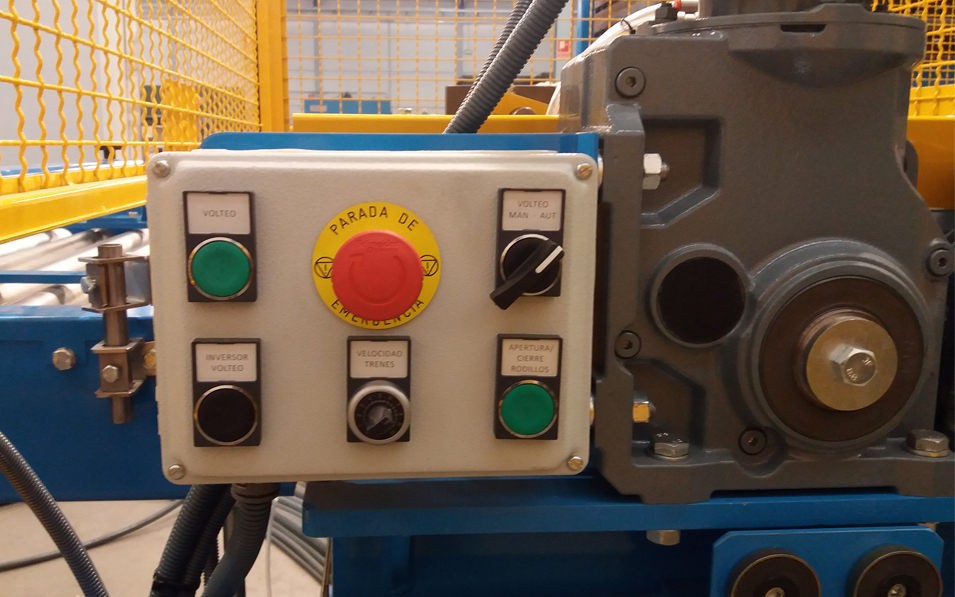

Independent control panel to activate the trains and the turning motor, in both directions.

Approved and integrated safety systems for the protection of machine operators.

AVAILABLE MODELS

VR116-058

VR136-058

Contact us and we will advise you on your project