Horizontal Palletizer

The HORIZONTAL PALLETIZER is the latest machine within which is a fully automatic production line for terrazzo tiles. It is a machine designed to avoid the human overexertion of tile palletizing by hand. The tiles are sucked through a suction cup and deposited on the wooden pallets, leaving the material ready for shipment.

PROCESS

-

Transport of the tiles through the different conveyors

-

Arrival to the grouping train, where they are placed by rows

-

Step to the placement train, row by row until forming the complete tile layers

-

Placement of the lite layers to be extracted by the use of some grippers

-

Extraction of them by the use of a suction head through vacuum

-

Automatic unstacking and placement of the wooden pallet

-

Unloading the tile layer on a wooden pallet

-

Once the loading of the pallet is completed, it goes to the withdrawal area

KEY FEATURES

CONVEYORS

Custom-built conveyors, depending on the installation of each customer.

Option of diverting the tiles using a 90º square or through a curved roll conveyor.

Possibility of manufacturing trains for 1 tile row, or for 2 rows, depending on the application.

Option to install 90º rotation device to adapt the position of 600x400mm format tiles to 1.000x1.000mm pallets.

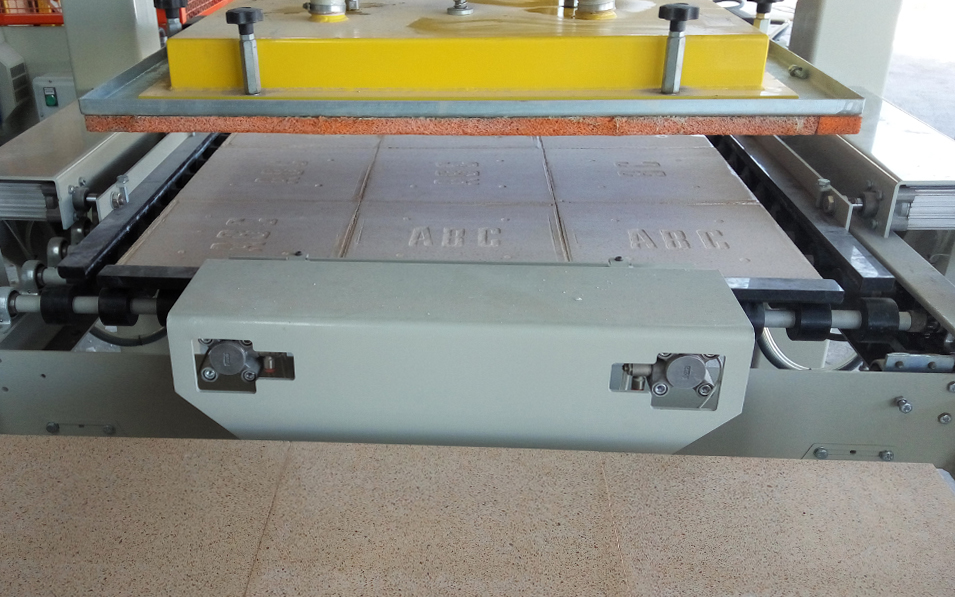

GROUPING AND PLACEMENT TRAIN

Grouping train, where tile rows are formed, depending on the tile format.

Possibility of grouping all tile formats, thanks to a simple regulation of the wheel stop.

Placement train, where the tile layers are formed, using pneumatic grippers.

Possibility of forming layers of all tile formats, thanks to a simple adjustment of the clamps.

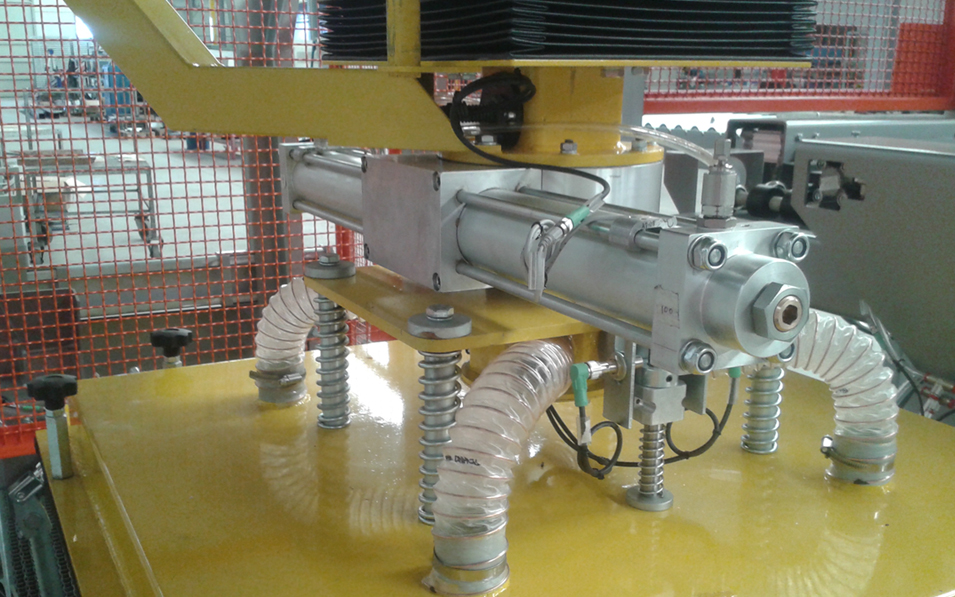

SUCTION HEAD

Suction cup head scrolling trolley, moved by connecting rod.

Elevation system controlled by encoder, for a smooth approach when unloading the tiles.

Possibility of manufacturing suction cups adapted to all tile formats.

Quick change of the different formats of suction cups by the use of wheels.

Option to add 180º rotation on the suction head to correct the ``wedge`` effect of the tiles on the pallet.

PALLET CHAIN CONVEYOR

Equipped with automatic unstacker and empty wooden pallet dispenser.

Regulations available in the automatic unstacker and in the conveyor for the different pallets.

Compatible pallet formats: 800x800mm, 900x900mm, 1.000x1.000mm, 1.200x800mm, 1.200x1.000mm and 1.200x1.200mm (model PLH-660).

Space available on the conveyor to store 2 fully loaded pallets and a third in load.

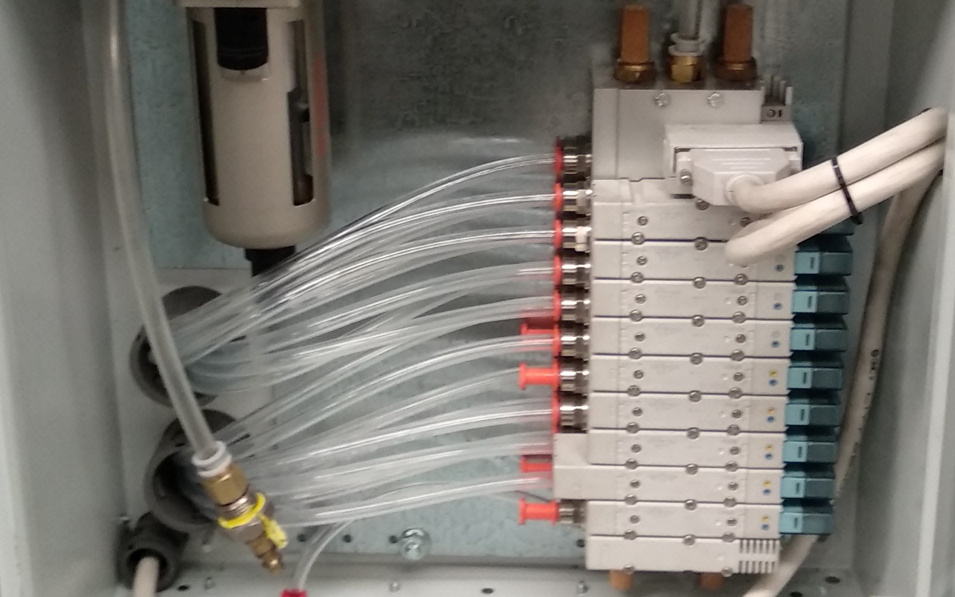

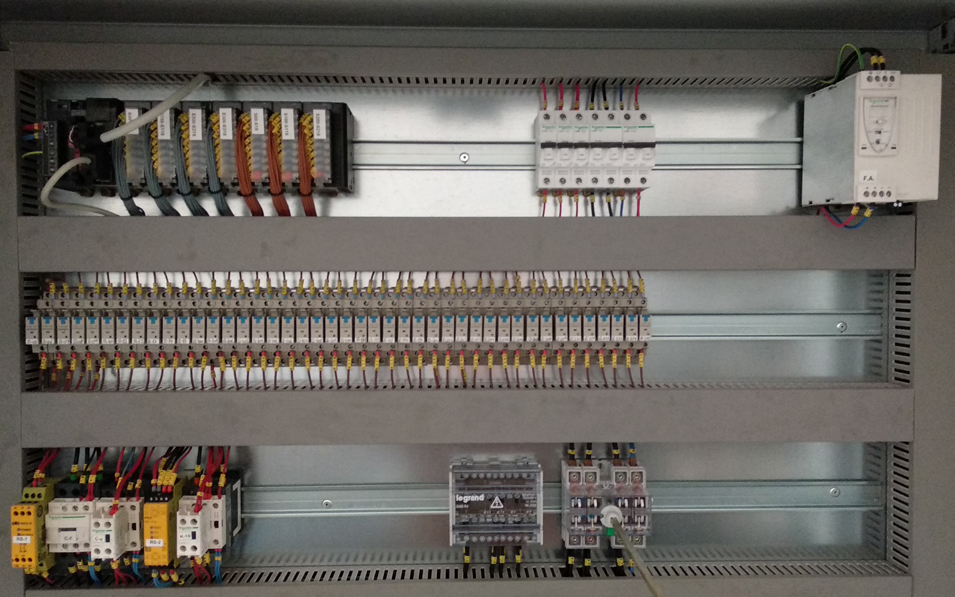

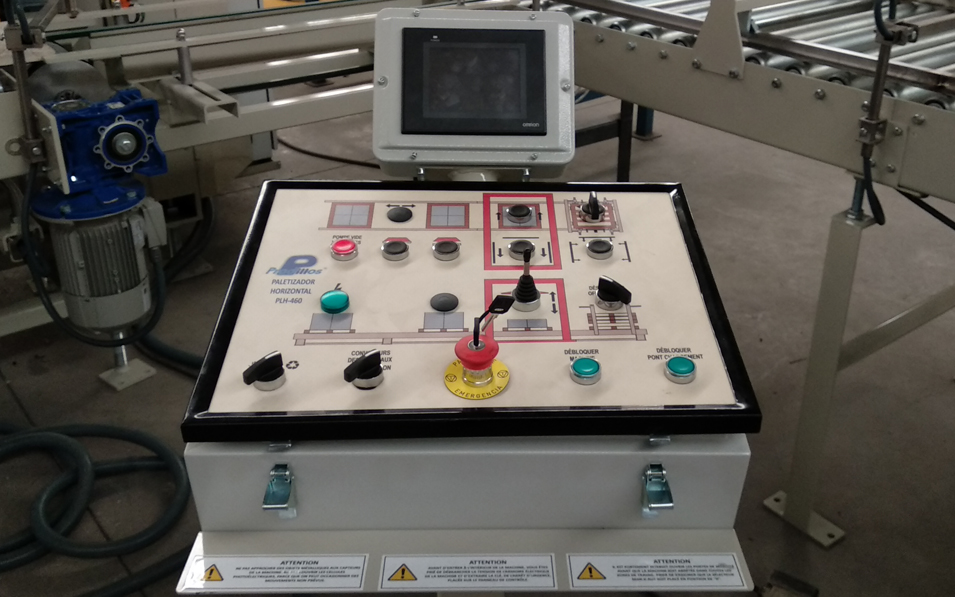

CONTROL SYSTEM

Complete electrical cabinet, with PLC control, for automatic operation of the entire installation.

5.6`` full-color touch screen for monitoring the whole machine and changing parameters.

Control Panel for selection of operating mode and total control of all elements manually.

Approved and integrated safety systems for the protection of machine operators.

AVAILABLE MODELS

PH-460

PH-660

Contact us and we will advise you on your project